Overview

This document will discuss the Warehouse Auto Transfer Application which is an add-on feature for Decor Fusion. This feature allows customers with a warehouse to centralize their ordering and then distribute to their stores based upon a weekly schedule. The application will generate transfers based upon minimums/maximums and reorder quantities and it will print to a specific printer so that the pickers can start pulling the orders from the warehouse.

Procedures

This document is divided into several sections, starting with setup.

Setup

- Please contact Sales(Patrick Carmody) to acquire a License for the application

- For assistance with the setup of Warehouse Automatic Transfers please contact Support

Execution Time

This application can be set to execute at any specified time via a Windows Scheduled Task.

Interface

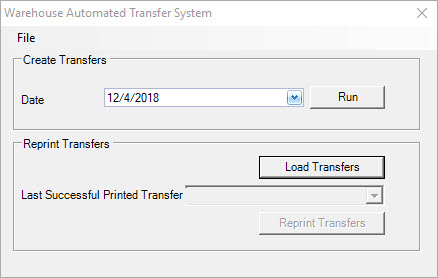

Date: Allows the override of the date to create transfers for

Run: Starts the process

Load Transfer: Loads the Dropdown list of the Last Successful Printed Transfers.

Reprint Transfers: Prints the selected transfer(s)

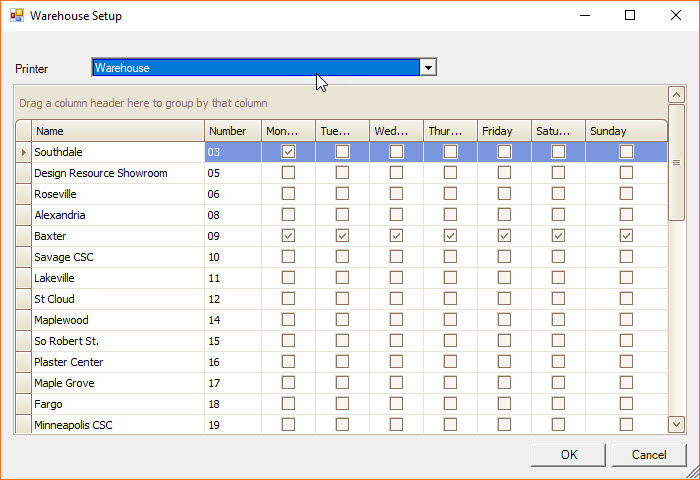

If you click on the File Menu and click Setup, the following screen appears,

This allows store transfer schedules to be created.

Specifications

- Items stocked in your warehouse are specified during the setup by setting the tertiary vendor to a specific vendor.

- Each store can have its own min/max/reorder set for a specific item. Based upon these values, an Inventory Transfer is created from the Warehouse to a store.

- If there is no/partial stock of a specific item at the warehouse then the item is back-ordered.

- The logic also does not allow for partial transfer fulfillment.

- During every execution, all open and back-ordered transfers are combined into one transfer as a sort of “house cleaning” so that you do not have lots of outstanding transfers.

- It is possible to have multiple backorder entries of the same item on a backorder transfer due to the combining of open/backorder transfers.

- The application will also attempt to fill any backorders before it processes new transfer items. Backorders must be fulfilled before you can fulfill any other transfers.

- If you cannot fulfill the backorder amount, the new transfers will be back-ordered even if you have onhand stock at the warehouse.

Available Calculation (At Warehouse)

The calculation which is used to determine how much stock is available at the warehouse is as follows:

Available = On Hand + (-1 * (Open Transfers/Backorders from Warehouse)) + (Open Transfers/Backorders to Warehouse) – Allocated

Note: The calculation takes the Back Order amount into consideration for each item instance on backorder by netting out the amount from the Available amount.

Scenarios

Warehouse Stock: 8

Store Suggested Order: 4

Open/Backorders: 0

Allocated: 0

In this scenario, the onhand at the warehouse would be 8 (8 + (-1 * (0)) + 0 + 0). A transfer would be created for 4 items.

Warehouse Stock: 8

Store Suggested Order: 0

Open/Backorders: Two backorders, one for 16 and one for 8.

Allocated: 0

Since there are backorders for this item, they will need to be processed first. The first backorder would be processed and the onhand at the warehouse would be 0 ((8 + (-1 * (24)) + 0 + 0) + 16). Note that the + 16 is the netting out of the backorder mentioned above. This item would be back-ordered. The second backorder for 8 would have a warehouse onhand of -8 ((8 + (-1 * (24)) + 0 + 0) + 8). This too would be back-ordered.

Warehouse Stock: 40

Store Suggested Order: 8

Open/Backorders: 20

Allocated: 0

In this scenario, the warehouse would fulfill the 20 item backorder. Once that is done then it would create a transfer for store suggested order of 8 leaving the warehouse with a total onhand of 12.